RAS Panel Bending Machines for HVAC Units and Filters

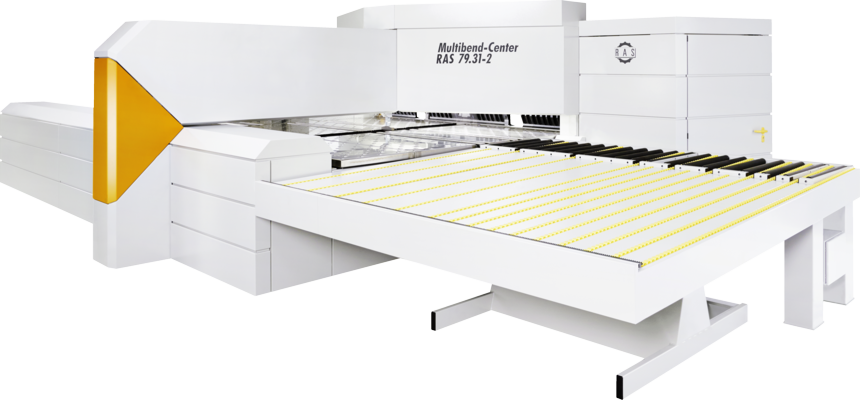

Panel Bending Body Parts of HVAC Units

Johnson Controls from Norman, Oklahoma (USA) bends the body parts of their air conditioners on two RAS Multibend-Centers panel bending machines. They market their HVAC units under the brand names of York, Luxaire, Fraser-Johnston and Coleman. The panel bender automatically folds the workpieces before an operator takes the bent parts from the buffer table. Manufacturing Engineer Tom Langford is enthusiastic about the reliability and precision of the two Multibend Centers.

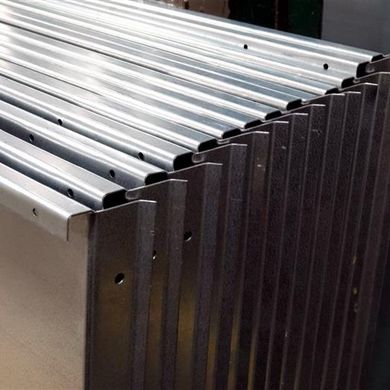

Panel Bending Parts for Filter Systems

The Rippert group produces latest paint and powder coating systems as well as the associated components for air treatment and air distribution. For the customized and innovative solutions, a high level of manufacturing flexibility is required. This also includes handling of low production quantities. The painting and air handling specialist focuses on the folding technology for all box and panels shape parts and in particular the RAS Multibend Center panel bending machine.

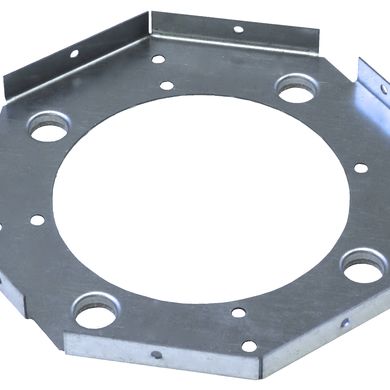

Panel Bending Machine Parts for Aircon Unit

The bending center RAS Multibend Center panel bending machine bends a multi-sided panel for an air conditioning unit. During the challenging bending sequence, UpDownTools are also used. They temporarily create gaps in the tool setup of the folding beam. They are automatically activated during the bending process.

RAS Panel Bending Machine Folds Fan Components

Parts of small fans can be very complex and create high demands on the automatic bending systems. The RAS MiniBendCenter a bending center for small parts starts with an automatic loading robot. Blanks can be either stacks or provided in bulk material boxes. The blanks do not need to be rectangular shaped, but can come in any outer contour. A tool changer automatically sets-up the bending cell. A manipulator moves the part to the individual bending stations, where the component will be bend up and down. In the runout, the finished parts can be lined up on a conveyor belt or pushed into bulk boxes

- Rox: Massanzug in der Klimatechnik

- Nolting: Heizluftgebläse

- MiniBendCenter: Lüfterteile

- Multibend-Center: Klimagerät (mehrseitig)

- Multibend-Center: Lackier-, Luft-, Filtersysteme

- UpDownBend: Dunstabzug in Großküchen