RAS machines for: Kitchen equipment and cleaning machines

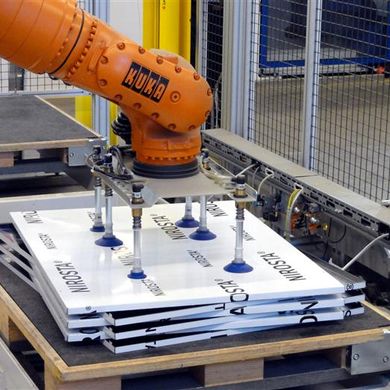

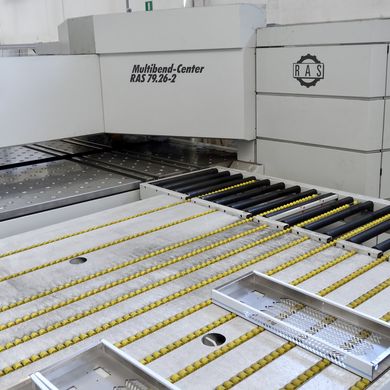

Multibend-Center bends steam ovens

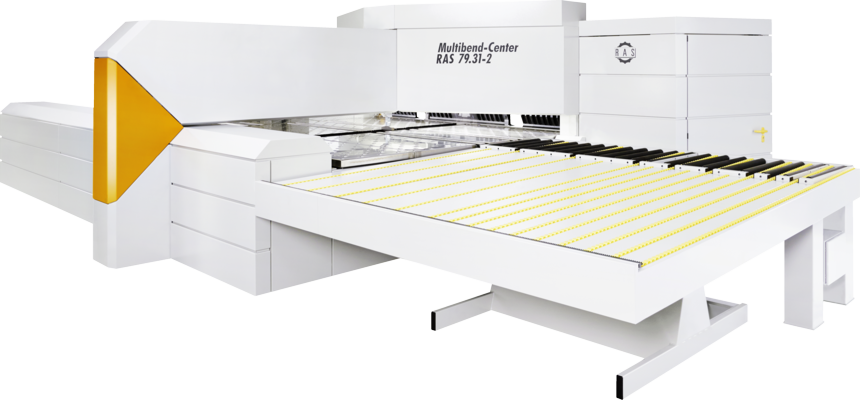

The RAS Multibend Center panel bender at Convotherm Elektrogeräte GmbH folds stainless steel parts for steam ovens. A loading robot feeds laser cut blanks to bending center. An unloading robot picks and stacks finished bent components. The intelligent loading and unloading robots require no programming. They calculate their movements all automatic.

www.convotherm.com

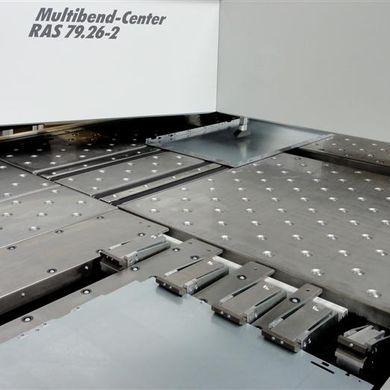

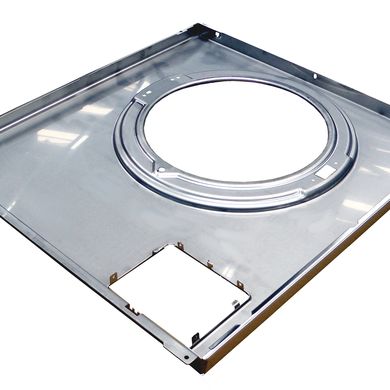

Bending commercial washers and dryers

While most companies just look for more productivity in metal bending, other producers use a more global approach. One of these companies is Miele & Cie. KG in Lehrte near Hanover. Short cycle times were not their main focus for the RAS Multibend-Center investment. Issues like fast machine set-ups, the use of already deep-drawn blanks, a multifunctional tool set, high levels of part design flexibility and system reliability as well as improved logistic sequences have been much more important.

www.miele.de

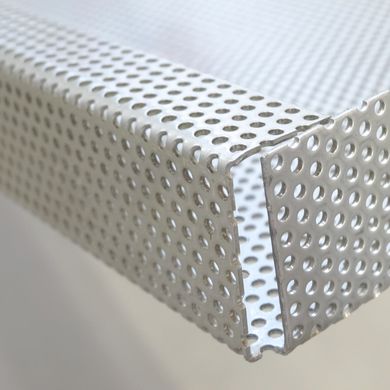

Ventilation ceilings for commercial kitchens

The video shows the RAS UpDown folding machine at Halton Foodservice GmbH in Reit im Winkl (Germany). The company, which belongs to the Finnish Halton Group, produces exhaust hoods and ventilation ceilings for commercial kitchens. The opposing bends were the main reason for investing in a RAS UpDown bi-directional folding machine.

www.halton.com

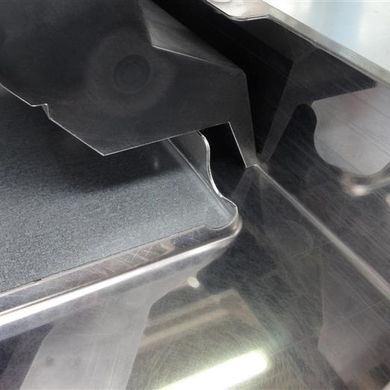

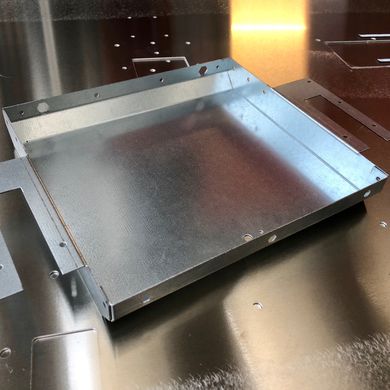

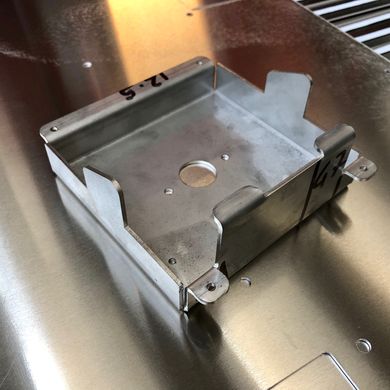

Kitchen appliance

Bending the front of a kitchen appliance on the bending center RAS Multibend Center. The large glass cutout in this complex stainless steel part requires machine features like repositioning of the main manipulator during the bending process, an asymmetrical tool setup and tool change within the bending sequence. Due to the unmatched bending accuracy, subsequent laser welding of the corners is possible.

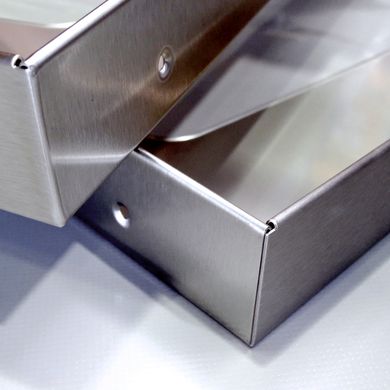

GIGAbend bends laundry equipment

STAHL Wäschereimaschinenbau manufactures laundry equipment already in the fourth generation. Among the customers of STAHL there are hotels, hospitals, laundries, handicapped work-shops, tanning salons, commercial laundries and many others. STAHL uses the GIGAbend RAS 76.40 for panels as well as for structural components up to 5 mm mild steel thickness on 4060 mm working length.

www.stahl-waeschereimaschinen.de

Chinese manufacturer of kitchen equipment

Bending of enclosure parts for commercial kitchens. Perfect interaction between two operators on a FLEXIbend folding machine enables a RAS customer in China to achieve extremely high productivity. Paired with the technical capabilities of the machine, throughput and efficiency can be significantly increased with excellent work organization.

www.fotileglobal.com

Inside wrappers of combi steamers

The RAS FLEXIbend bends radii on inside wrappers of combi steamers using a radius tool. The lower beam tools are segmented and can be set up for the inside wrapper length. A slot in the lower beam tool setup is needed for the down facing flanges.

www.convotherm.com

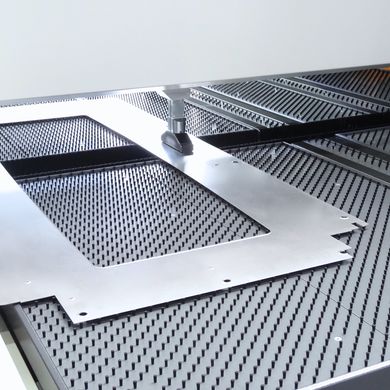

Scanning blanks for cooker hoods with camera system

The panel bender RAS Multibend Center folds cooker exhaust hoods. Due to the special shape of the blanks, a normal squaring process cannot be used. However, a camera system recognizes the shape of the blank, loads the bending program and sends the position data to a loading robot, which loads the blank precisely to the bending center.

www.neff-home.com

Bending stainless steel refrigerator doors

Stainless steel doors of refrigerators have a high demand on the optical finish of the door. The bending center RAS Multibend Center uses a patented bending process that does not scratch the material surface of the stainless steel refrigerator doors. Tecnodom SpA produces refrigerator doors and components of refrigerated counters and cold rooms on several RAS bending centers with automated blank loading.

www.tecnodomspa.com

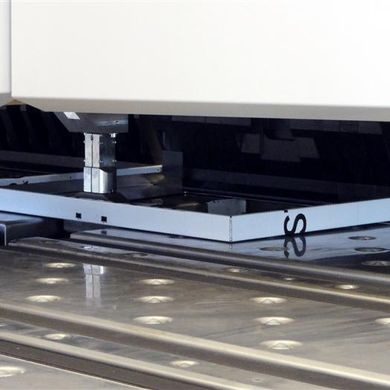

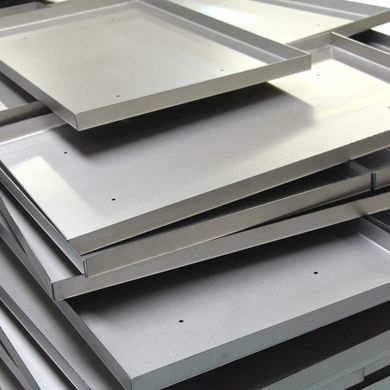

Stacking bent parts for pizza ovens

XLT Ovens is a leading manufacturer for pizza conveyor ovens and exhaust hoods. The video shows the automatic unloading of bent parts on a Multibend Center RAS 79.26-2 panel bender. An intelligent unloading robot, which must not be taught or programmed, stacks the parts on pallets. A pallet tower automatically feeds the pallets. If the finished parts should be stacked vertically, the robot attaches a back panel to the pallet, before stacking begins.

www.xltovens.com

MiniBendCenter bends Coffee machines

Iron Sistemi in Italy uses a MiniBendCenter for automated bending of small and very complex components. There is no other system available on the world market than the RAS MiniBendCenter covering such a wide scope of products. The owners Valerio and Filippo Bolpagni proudly present the stainless steel front of a coffee machine composed of several individual parts that are precisely bent and perfectly match to each other.

www.ironsistemi.it

- UpDownBend: Dunstabzug in Großküchen

- FLEXIbend: Küchenteile

- UpDownCenter: Kühltheke

- Multibend Center: Kühlschranktüren

- Multibend-Center: Dunstabzugshauben

- Multibend-Center: Front eines Küchengeräts

- Multibend-Center: Dampfgarer

- Multibend Center: Waschmaschinen und Trockner

- Multibend-Center: Roboterentladung von Pizzaöfen

- 1

- 2