RAS machines for: Facade panels and profiles

Bending large architectural facades cassettes

The company Les Ateliers de Yèbles as a job shop has specialized in the production of facade elements. The requests of the architects sometimes are very special and constantly require new part design variations from the technical department at Yèbles. Flexibility is also needed in production as the production quantities often only range between ten and forty identical parts. The RAS UpDownCenter meets these requirements brilliantly.

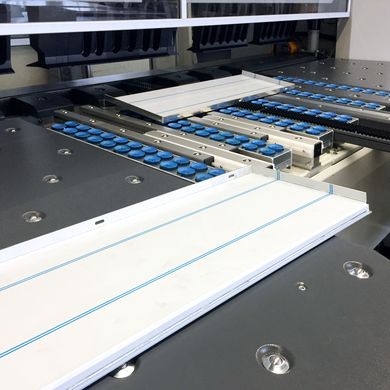

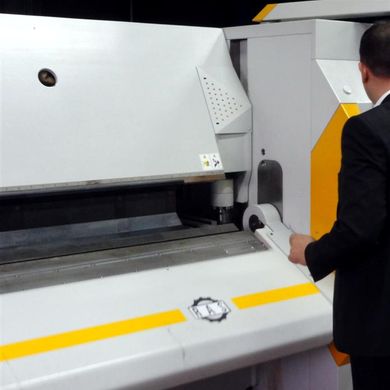

Bent metal parts for glas facades

Anyone who imagines a skyscraper with a glass facade probably does not think about how many bent metal parts it contains. The Canadian company BVGlazing has specialized in this industry and bends the parts using an XLTbend UpDown folding machine. After importing a STEP file of the part, the Bendex software calculates the ideal bending sequence. The operator at the machine only calls up the provided program and places the tools in accordance with the setup instructions, Stop fingers position the blank for each bend on the bend line. Suction cups in front of the stop fingers hold the part in position. This allows the updown bender to automatically process complete sequences with multiple positive or negative bends without the operator being involved in the actual bending process.www.bvglazing.com

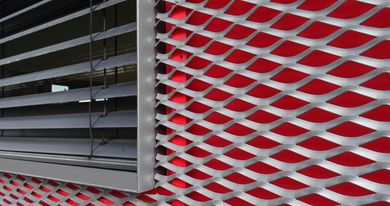

Modern architecture

The Czech company AD-Tech s.r.o. created for company Sipral a.s. the entire facade panels for the New Engineering Building at Sheffield University called “The Diamond” on a RAS FLEXIbend metal folding machine. This fascinating building is a fantastic place for teaching and learning. The engineering classes moved into the building, which houses lecture theatres, seminar rooms, laboratories, a library, social spaces and cafeterias.

Geerds relies on UpDown technology

Geerds Metallbau GmbH brings over 40 years of experience and competence to its facade projects. The facade specialists from Groß Welzin combine innovative product technology with state-of-the-art production technology. The RAS UpDownCenter complements the range of services of this leading supplier in facade technology. The Bendex software programs the bent parts with a single mouse click. With the automatic tool change and scratch-free metal folding technology, Geerds can also bend complex and optically superior components in small quantities with high profitability.

www.geerds.de

GIGAbend in metal construction

Tecnic Metal Listes near Barcelona, Spain, is a metal builder specialized in the metal doors, projecting roofs, fireplaces, stairs and window frames. May the special requirements of the architects be extremely special, Angel Rodriguez and his team, will take any challenge. With the RAS GIGAbend and several sets of tool, the small company meets nearly all requirements. Angel Rodriguez appears perfectly satisfied with his decision for the RAS GIGAbend. “The machine has so much free space that we can custom-design parts profitably even in small batches.”

www.tecnicmet.com

Bending cable car station

Where formerly cable car stations were located in windy heights, skier and hiker nowadays expect a luxury ambience. Modern cable car station today are comfortable building that offer much more than just wind and weather protection. The lift stations of the Doppelmayr cable cars are known worldwide. Salzmann Formblechtechnik GmbH produces the sheet metal covers for cable car stations on a RAS GIGAbend folding machine.

www.formblechtechnik.com

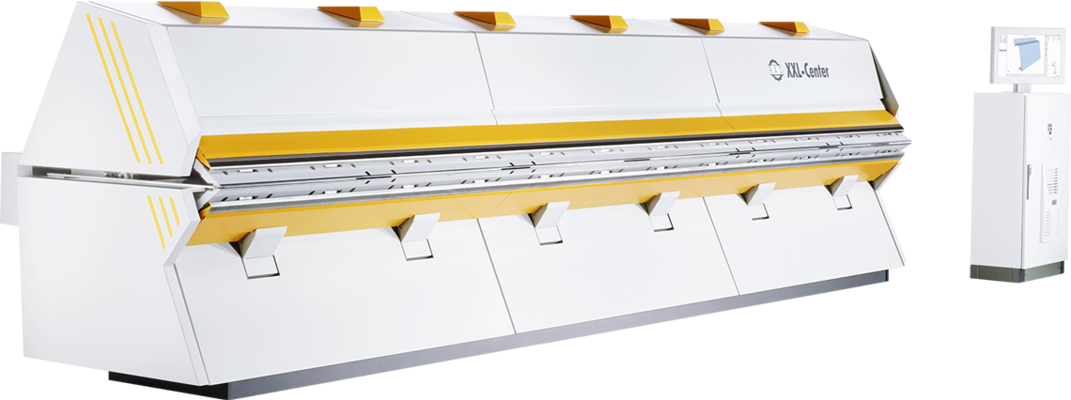

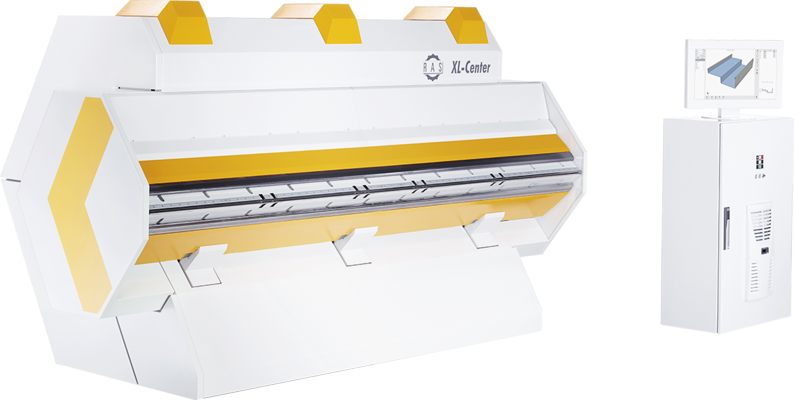

- XL-Center: Blechnerei Schwär

- Gramm: POWERcut2

- Burckhardt-Gruppe: Der digitale Metallbauer

- UpDownCenter: Alu-Verbundfassade

- UpDownCenter: Eingehängte Fassadenkassette

- UpDownCenter: Metallfassaden

- XL Center bei Karl Schmidt GmbH