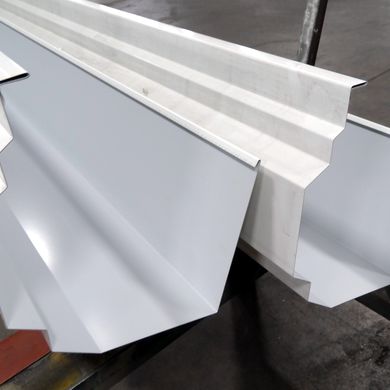

RAS machines for: Roof and wall profiles

New business segment with XXL-Center and Bendex

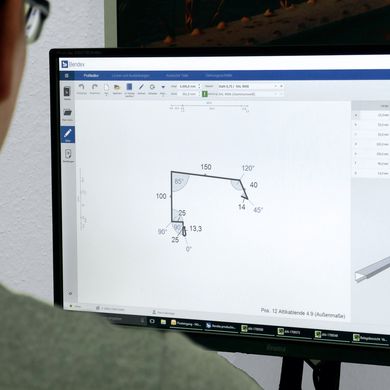

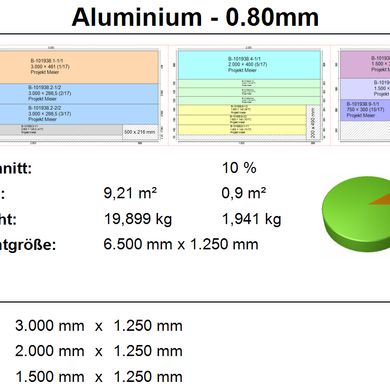

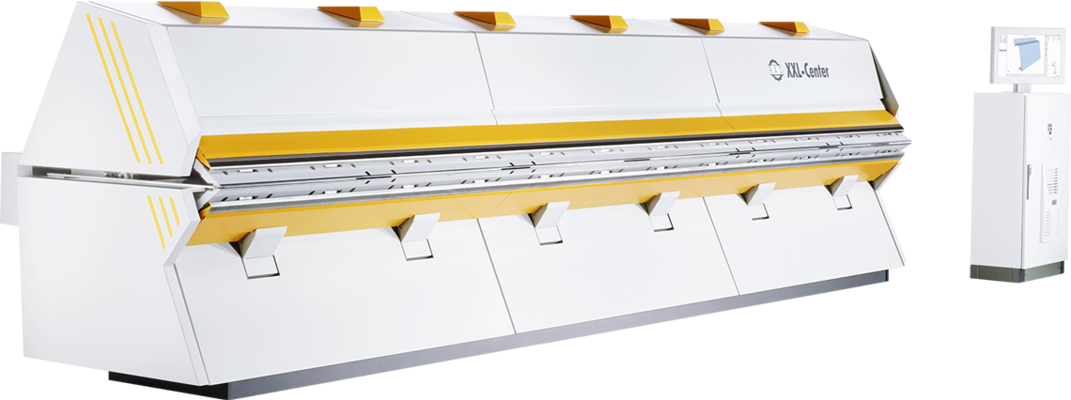

On their homepage, Schütze GmbH reports that they have invested in a slitting line and a state-of-the-art XXL-Center long double folding machine. This allows them to produce and deliver profiles for roofs and walls quicker and more economically. The secret of success is, however, the organization in the background using the Bendex.professional software. Only the combination of machine and software led to this achieved efficiency.

www.schuetzegmbh.de

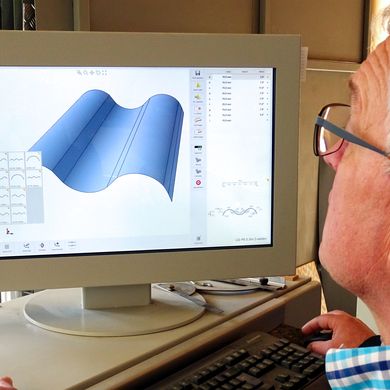

Bending roof tile profiles

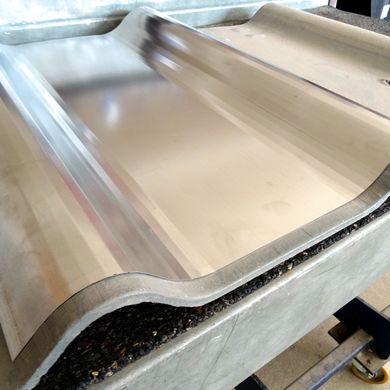

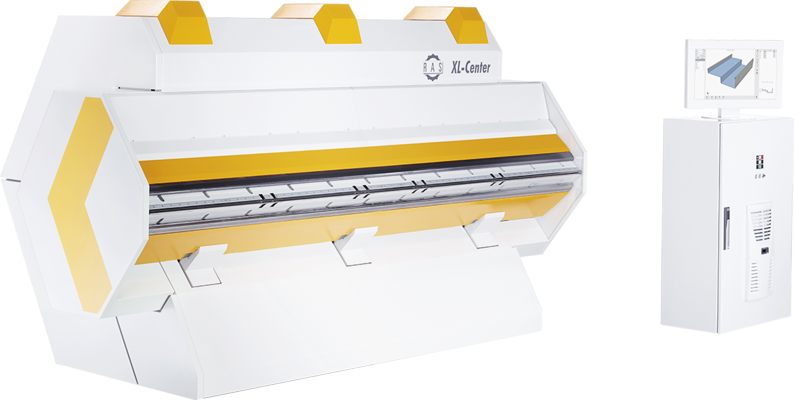

Manfred Baldauf and his wife first saw the RAS XL-Center at the DACH+HOLZ (Roof+Wood) show and immediately fell in love with the machine. The roofing and tinsmith company from Doren (Austria) works on both residential housing construction and with commercial developers and builders. The capability to form unique and unusual facades has most impressed Manfred Baldauf and the RAS XL-Center can bend exactly these profiles with whimsical shapes, radii and hems.

www.dicht.at

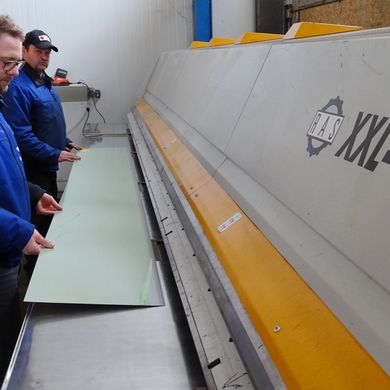

Made for speed

In 2014, Feilmeier AG wanted to acquire an additional long bending center with bidirectional bending; they wanted a machine that can bend the metal both up and down without any flipping of the part required. Key to their decision to purchase a RAS XXL-Center was the fully integrated Bendex-Software, which automatically programs the parts. The firm’s owner Ludwig Feilmeier had a clear vision of what he expected from his new machine. The large space in front of the folding beam allows Feilmeier to bend parts that they could not offer before.

www.feilmeier.com

Digitizing the Construction Site!

Stefan Bern is a roofing and façade specialist for demanding residential buildings. With a team of 30 employees, the company produces all metal parts in their workshop. Their own skilled workers assemble the profiles on large private

properties in the area. With the RAS XL-Center, the company has significantly increased its efficiency and bending speed.

www.stefanbern.de

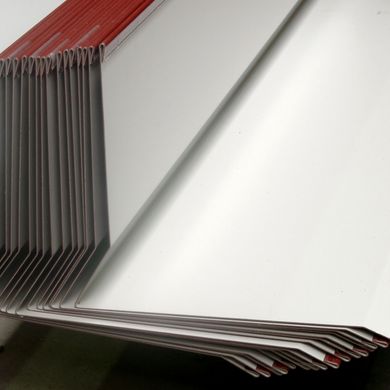

Now also in 8 meter length …

The well-known Schrag Group is specialized in the production and distribution of roof and wall profiles for industrial buildings. In order to achieve their goals of reliability, speed and quality, the Schrag Group uses several XXL-Center long folding center from RAS which automatically programs the profiles. Technical director Bernd Wurmbach has noted: “If we run a 0.75 mm part 5 meters long with six to seven bends, the XXL-Center is about 50% faster than our other bending machines.”

www.schrag.eu

From YouTube to a finished part

When Carl Schmidt began looking for a new metal folding machine to produce profiles for commercial construction, he took an unusual route. Instead of visiting trade shows or different manufacturers, he started watching YouTube clips of the different manufacturers. He was so impressed by the RAS XL-Center that he decided to place an order without ever seeing the machine live. What might seem to some like a rushed action was, in reality, carefully thought through.

www.karl-schmidt-gmbh.de

Quick and accurate

In November 2002 FN Profilblech Center GmbH from Bad Rappenau, Germany, installed a RAS XXL-Center. Today the specialist for folded roof and wall parts cannot imagine how they were able to run their business without the high-performing long folding center. What took three shifts on a press and a traditional long folder before, is now completed in one and a half shifts on the XXL-Center.

www.fn-profilblech.de

XXL-Center at H&H Architectural Metals

Jim Huff, owner of H&H Architectural Metals from Denver proudly says: “In the past we needed 20 minutes with 2 people to bend a complicated gutter. With the RAS XXL-Center we run 2 gutters at a time in 2 1/2 minutes with a single person.” Machine operator Kevin pulls two metal blanks from the side onto the machine’s sheet support tables. The XXL-Center automatically squares the blanks and runs the parts completely automated. Jim Huff says with a smile: “35 years ago, my wife Kathy and I founded H&H Architectural Metals with $ 6 and 38 cents starting capital.” Today the company operates in their own 5500 sqm building with the latest machinery equipment. The succession is also secured by son Chad Huff.

www.h-hmetals.com

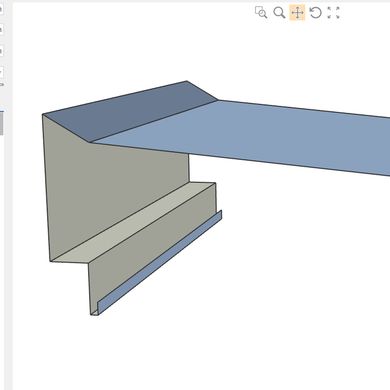

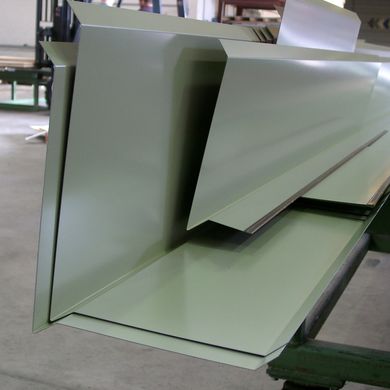

Metal fabrication with up-down bending

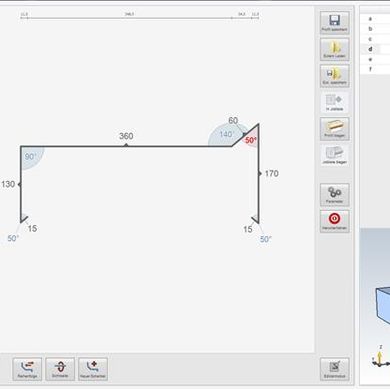

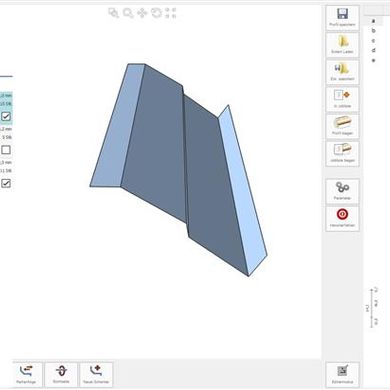

Roofer Leib reports on their Website: “As a result of the growing demands of modern architecture, ever more complex metal profiles are required. We can produce them now efficiently and precisely by the purchase of a new XL bending center from RAS. The required profiles can be designed directly in the office and sent to the machine. The machine geometry allows the metal to be folded in two directions, which saves expensive material handling time.”

www.spengler-leib.de

XX-fast with XXL-Center

Since March 2002 Rudolf Wiegmann Umformtechnik from Bersenbrück in Germany have produced folded profiles for roof and wall with an XXL-Center from RAS Reinhardt Maschinenbau GmbH. The sheet metal specialist processes 2500 tons of coil material and 200 tons of blanks per year. A well equipped steel and

aluminum warehouse, fast and precise production, as well as their own assembly company made the Wiegmann Group a respected and reliable partner in the industrial building industry.

www.wiegmann-gruppe.de

Speedy production

The Altvater GmbH is specialized in roofing and architectural components. Simon and Altvater follow a simple rule: “Lastest machine technology allows producing more profitable.” Shortly after they have received the FLEXIbend, Altvater received a big order for aluminum parts. The calculation was based on an older long folding machine. The FLEXIbend however, with a single operator

bends almost twice as fast. Therefore, they decided bending the parts only in lengths of 3000 mm. Altvater smiles: “We have made a good profit with this order.”

www.altvater.de

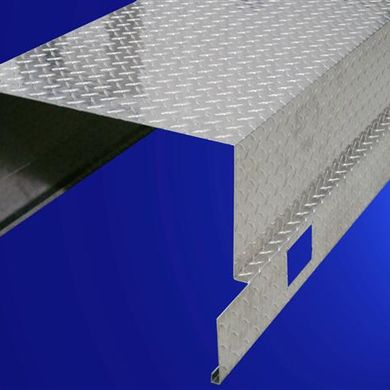

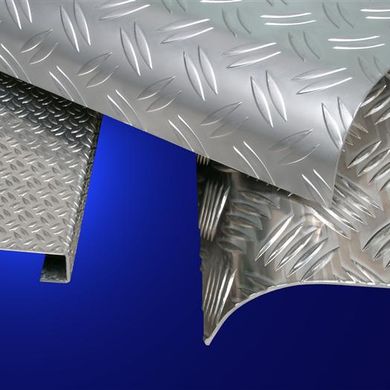

Tread Plate Folding

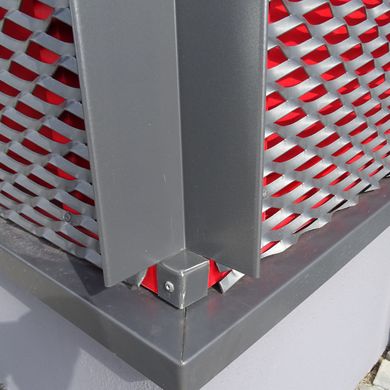

Tread plates are often used in the automotive industry as non-slip loading ramps on trucks, for tool boxes on pick-ups and for emergency vehicles and fire trucks. Tread is also common in the machine tool design. In industrial building construction, aluminum and steel tread plates are used for stair step designs. RAS folding systems can fold these often large sized blanks precisely and accurately with little effort.

- Lübke baumetal: XLTbend 45 Grad Oberwange

- FLEXIbend: Schmales Hutprofil

- XL-Center: Blechnerei Schwär

- XL-Center: Binder

- XL-Center: Dachfirst biegen

- XL-Center: Mauerabdeckung

- XXL-Center: Komplexes Wandprofil

- XXL-Center: Lichtkuppel

- XL-Center: Rollladenkasten

- XL Center bei Karl Schmidt GmbH

- XXL-Center mit Rollenschere

- 1

- 2

- 3