Metal folding machines give sheet metal its shape and are used in various industries for different products and projects. Semi-automated and fully-automated metal folding machines allow job shops to increase their productivity and lower production times.

However, often companies are uncertain about the level of automation they require during their evaluation process. The level of automation required will depend on the volume, variety, thickness, size, and depth of the part.

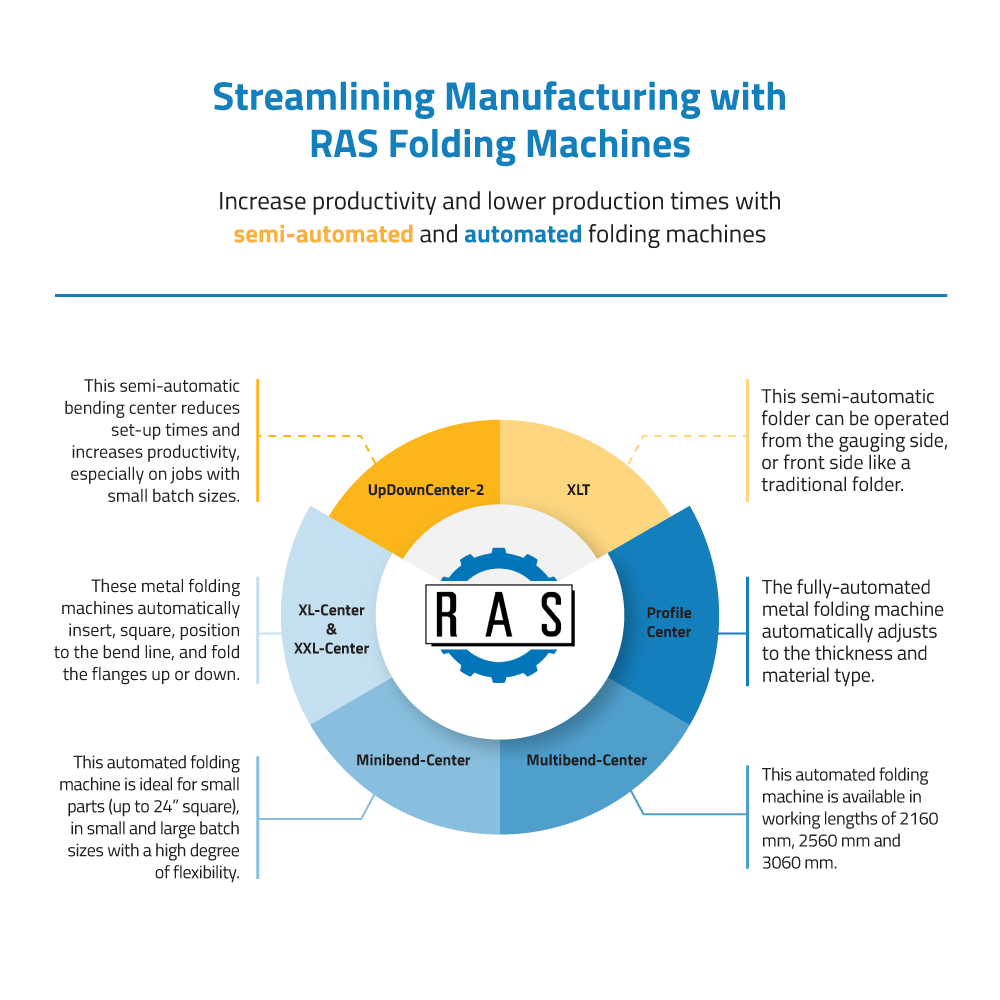

RAS Systems manufactures semi-automated and fully-automated folding machines ideal for companies looking to maximize automation.

Semi-Automated Machines

For companies that deal with a lot of flipping of parts, positive and negative bends, we recommend a semi-automated Up/Down folder. This type of folder is a bridge to full automation and makes an operator much more efficient due to less gaging and material handling. Machines with tool changers allow for an even faster changeover between parts and are simple for a single employee to program, operate, and set up.

RAS Semi-Automated Folding Machines

UpDownCenter-2: This semi-automatic bending center is operated from the gauging side. The tool changer reduces set-up times and increases productivity, especially on jobs with small batch sizes. Besides the up and down folding capability and automatic tool change, another highlight of the UpDownCenter-2 is the automatic one-click Bendex programming software. This machine is ideal for heavier gages and taller parts, such as electrical enclosures.

XLT: This semi-automatic folder can be operated from the gauging side, or front side like a traditional folder. This machine bends up and down, with manual tool change for a more economical solution in the mid-gage ranges. Bendex software is also included on this machine. Metal door skins and frames are common on this machine.

Fully-Automated Machines

Companies with a higher volume and variety of parts might require fully-automated metal folding machine. Other factors that come into play are the size, thickness, and material of the part and the depth of the finished part.

RAS Systems manufactures several different models of fully-automated metal folding machines that can help companies meet their requirements.

RAS Fully Automated Folding Machines

ProfileCenter: The fully-automated metal folding machine provides a high level of precision and repeatability. The machine automatically adjusts to the thickness and material type. The automated bending sequences lead to short cycle times and low costs per part. Part flipping is automated as well as up / down bending. This machine is ideal for tight bends and complex profiles, such as those found in the door frame markets.

Multibend-Center: This metal folding machine bends precision parts fully automatic, at very high speeds, in high quantity, regardless of batch size, with the highest levels of flexibility and total repeatability. The RAS Multibend-Center is available in working lengths of 2160 mm, 2560 mm and 3060 mm. A wide range of blank loading and finished part takeaway options are available also.

Minibend-Center: Ideal for small parts (up to 24” square), in small and large batch sizes with a high degree of flexibility. Fully automated loading / sorting and bending is offered. Tool changes happen on a per part basis if needed. Also, the machine can pull from random groups of parts without the need for pre-sorted stacking.

XL-Center & XXL-Center: These metal folding machines automatically insert, square, position to the bend line, and fold the flanges up or down. They virtually eliminate the need for rotation, complicated handling, and a second or third operator. The XXL-Center automatically produces precision long parts in record time, often for the metal construction market.

Contact RAS Systems

Please contact us if you have any questions about metal folding machines. Our team will understand your requirements and recommend whether a semi-automated or fully-automated machine will be right for your job shop.

Founded in 1939, RAS builds metal bending, cutting, and forming equipment, as well as fabrication software, and is known for its high quality, reliability, and accuracies.