Bendex Partner Program

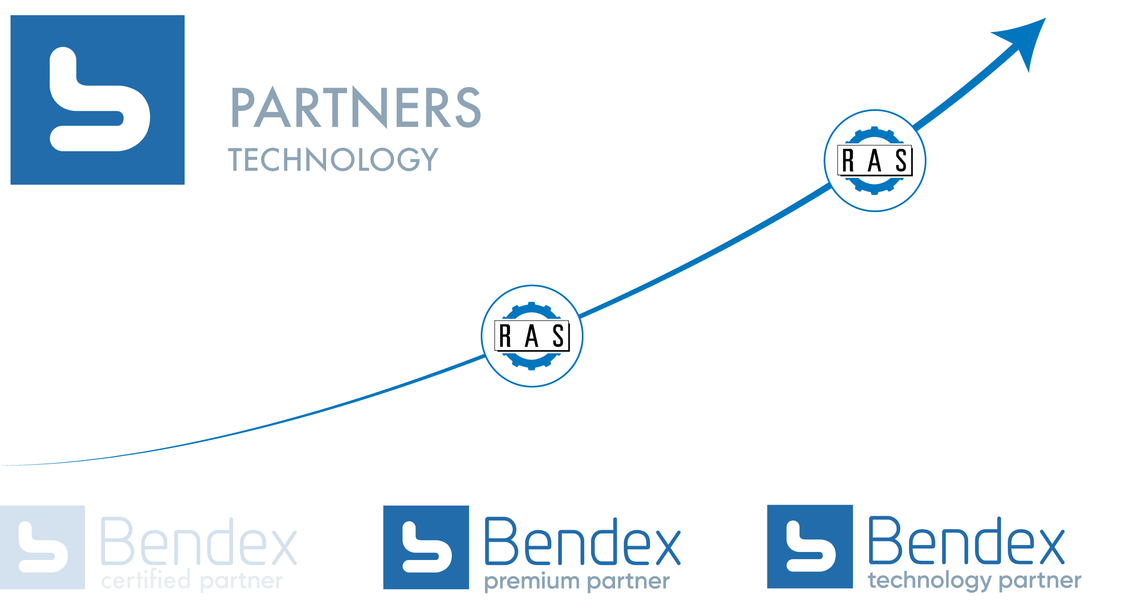

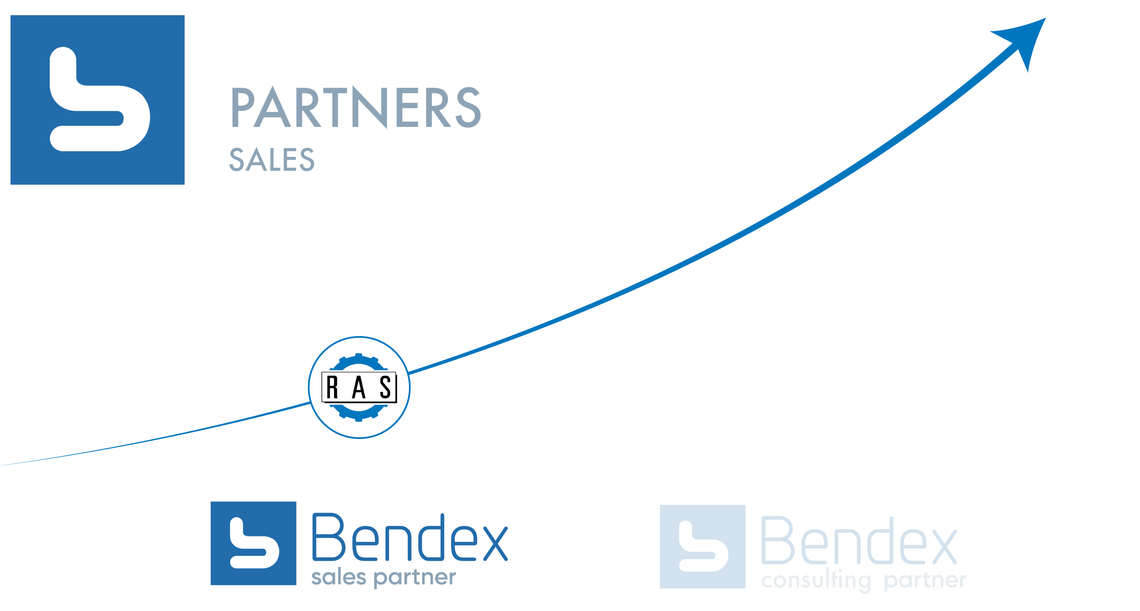

Bendex software has been established worldwide as a platform for sheet metal production addressing the company organization and the machine-related environment. A partner program shows the intensity of the cooperation in sales and technology. RAS has reached the highest levels of cooperation. The following logos illustrate the quality of the software solutions.

Technology

Sales

Premium Partner:

As a Premium Partner, RAS offers the most powerful software integrations. This starts with the import of part geometries in countless data formats (STEP, dxf, dwg, geo, etc) and the analysis, preparation and import of the CAD bending part data.

It is also possible to export the part geometries in the most common data formats (STEP, dxf, dwg, geo, etc).

Sales Partner:

As a Sales Partner, RAS has trained sales personnel and can support customers on any of the Bendex software products. As a Sales Partner, RAS distributes, installs and trains Bendex solutions. The product range supported by RAS includes:

- Bendex Machine Software for RAS metal folding machines

- Bendex Office Software for RAS metal folding machines

- Bendex Update Contracts for new features and software updates

- Bendex Professional Enterprise Software

Technology Partner:

RAS is the only manufacturer of sheet metal working machines who has reached the “Technology Partner” level. This means that the Bendex runs as the control software on RAS folding machines. The logo “powered by Bendex” on the machine indicates this complete integration.

They full integration includes for example:

- Machine control with Bendex software

- Office programming with Bendex Office software

- Automatic programming of the bending sequences

- Visualization of different bending alternatives with a 5-star rating

- Simulation of the bending sequence in a 3D view already in the Office Software

- Bidirectional communication between machine and office ensures that the bending sequences are based on current machine data. For instance, the actual travel distances of the axes or the tools currently available at the machine are imported and incorporated for programming the bending sequences.

- During the automatic programming of the bending sequence, material tables consider the specifications of different materials when bending different sheet thicknesses, leg lengths and angles.

- Creation of individual part catalogs.

- Sending of bending programs or job lists with job sequences from the office to the machine.

- With a data model of the machine, the Bendex software considers the impact of the machine deformation on the bending result.

- The tools are stored in the software with a wide range of metadata. Thus, the Bendex software knows, for example, the maximum free space around a tool and its bending capacity.

- Calculation of real cycle times for quotations, including handling times for loading, turning, flipping and unloading of bent parts with different sizes and weights.

- Service modules: Analysis of the operating times of individual axes and indication of service points.

- Application profile: Stainless steel parts often have higher quality requirements than a general sheet metal components. By selecting a application profile, you can specify whether a tool setup should be with gaps between the tools or without gaps. The gap-free set-up results in visually perfect stainless steel parts, but may lead to longer setup and bending times.